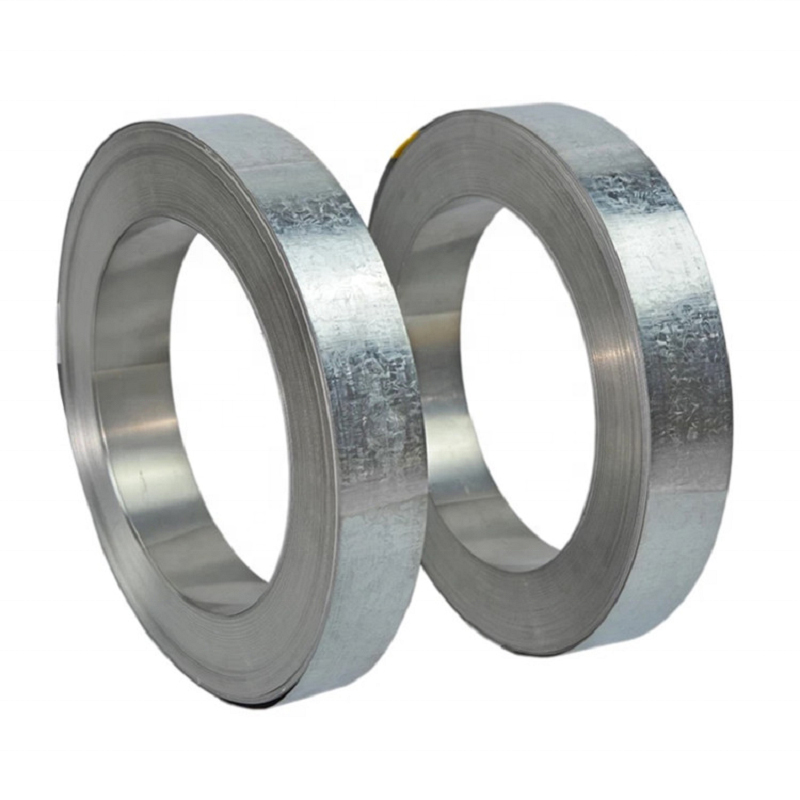

Galvanized Steel Strips

1. Corrosion resistance: The zinc layer on the surface of the galvanized steel strip can provide good corrosion resistance and prevent the steel strip from contacting moist oxygen and other corrosive media in the environment, thereby extending the service life of the steel strip.

2. High strength and hardness: After the galvanizing process, the strength and hardness of the steel strip itself will not change significantly. This allows galvanized steel strip to be useful in some applications where higher material strength is required.

3. Good processability: Galvanized steel strips can be processed and formed by cold rolling, cutting, shearing, etc. to meet the needs of different applications.

4. Good thermal stability: Galvanized steel strip has good high temperature resistance and can maintain stable performance in high temperature environments.

5. Easy to detect: Galvanized steel strips can be visually or simply inspected to verify the presence of a galvanized layer on their surface, making them easy to perform quality control.

Product description

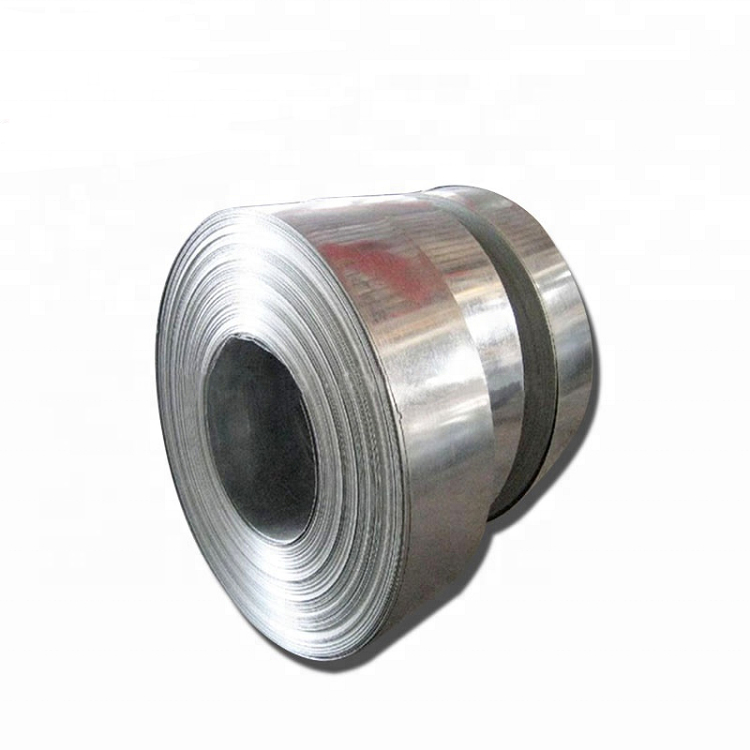

Galvanized steel strip is a metal material made by plating a layer of zinc on the surface of the steel strip. The process of galvanizing is mainly realized by hot dipping or electroplating.

Product parameters

Material | Q235 Q195 / Q235 / Q345B / DB460 ASTM/AISI/SGCC/CGCC/ TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345 |

Thickness | 0.12-6.0mm |

Width | 20-1500mm |

Zinc coating | Z40-600g/m2 |

Coil weight | 3-8 Tons or as requirement |

Surface | Galvanized Coated |

Certificate | ISO,SGS |

Galvanized steel strip production process

In the production process of galvanized steel strip, very strict procedures and multiple production processes are required. Below I will introduce the production process of galvanized steel strip.

The first step is to clean and decontaminate the strip surface using a pickling process. Because the dirt and rust that usually exist on the surface of the strip may affect the galvanizing work on the surface if it is not cleaned. Generally, the strip steel is uncoiled after pickling, and then cleaned to make the surface clean and tidy.

The second step is to roll the strip to the desired thickness and smooth the surface. After rolling is completed, the next step is galvanizing. The galvanizing work is actually very simple, just put it into a hot dip tank, control the time and temperature, and you can get a smooth and uniform coating. Finally, put it in the warehouse and you're done. The thickness of the galvanized layer is not fixed and can be processed according to the different needs of customers.

Application

Galvanized steel strip is a new type of material. The principle is to coat a layer of zinc on the surface of the steel plate and use the physical properties of zinc to play an anti-corrosion role. As a new material, galvanized strip steel is the most widely used in construction and light industry, accounting for about two-fifths of the total application.

In addition, galvanized strip steel, as a kind of anti-corrosion treated steel, is also widely used in daily life. Just because of the different uses and processing forms, we may not notice it, such as the ventilation ducts of buildings, and some electrical appliance surfaces. After beautification, they are usually used in places we can't see, such as the back cover of refrigerators, etc.