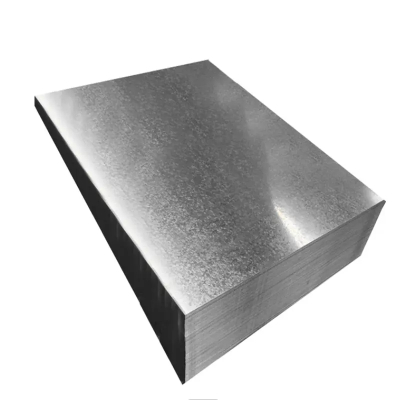

Corten Steel Plate

COR-TEN has served as weathering steel (atmospheric corrosion- resistant steel). Corten steel plate has successfully overcome rust, steel’s most weakest. When exposed to the atmosphere without painting, corten steel begins to rust in the same way as ordinary steel. BUT soon the alloying elements in COR-TEN cause a protective surface layer of the fine-textured rust to form, thereby suppressing corrosion rate. Since its development in 1993, the COR-TEN has been used in every field where steel applied, such as bridges, railway vehicle and buildings. At present, COR-TEN are attracting attention as being suited for resources and environmental concerns as well as reducing life-cycle costs.

Weather-resistant steel plate, also known as weather-resistant steel plate and corten steel plate, is atmospheric corrosion-resistant steel. It is a low-alloy steel plate between ordinary carbon steel plates and stainless steel plates. Weathering steel is high-quality steel made from ordinary carbon steel with a small amount of copper, nickel and other corrosion-resistant elements added. It has the characteristics of high-quality steel, such as toughness, plastic extension, forming, welding and cutting, wear resistance, high temperature resistance, and fatigue resistance.

Highly weather-resistant structural steel is mainly used for bolting, riveting and welded structural parts of vehicles, containers, buildings, towers and other structures because its atmospheric corrosion resistance is better than that of weather-resistant steel for welded structures. When used as welded structural parts, the thickness of the steel should not be greater than 16mm. The welding performance of weathering steel for welded structures is better than that of high weathering structural steel, and it is mainly used for welded structural parts of bridges, buildings and other structures.

Product name | Corten steel/carbon steel sheet |

Size | Thickness:1.5mm-300mm |

Special specifications can also be produced according to drawing and sample | |

Length | 6000-12000 mm depend on requirement |

Width | 1000-3000mm |

Material Grade | SS400, ASTM A36, A572,ST37,ST52,Q195, Q215, Q235,Q345,S235JR, S355JR, S45C, S50C |

Standard | GB/T709-2006, ASTM A36, JIS G4051, DIN EN 10083, SAE 1045, ASTM A29M |

Surface | Smooth, straight, bright, no blur on both ends |

Packing | Export-sea worthy packing with each bundle tied and protected |

Application | 1.Automobile, Bridges, Buildings. 2.Machinery, Pressure vessel industries. 3.Ship building, Engineering construction. 4.Mechanical manufacturing, Pavement slab, ect. |

MOQ | 1 ton each size |

Delivery Time | immediately in stock or depend on order quantity |

Processing technique | 1.Heat treatment facilities for hot-rolled, controlled rolling,normalizing. 2.Annealing, tempering, quenching, normalizing plus tempering, quenching and tempering. 3. Other delivery states are available as customers’ requirement. |

Payment term | T/T, L/C etc. |