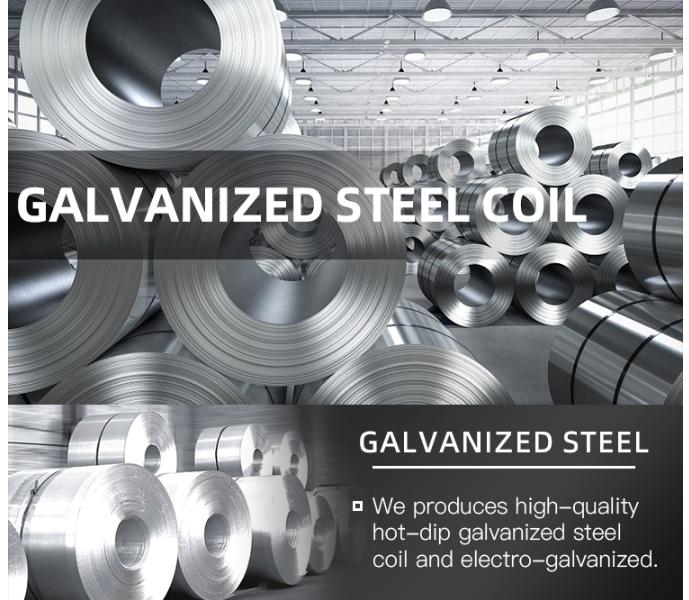

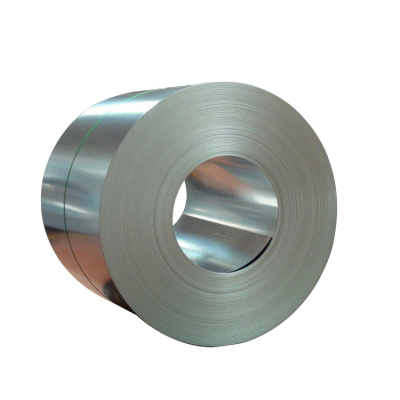

Galvanized Steel Coil

1. Good corrosion resistance: Zinc has high corrosion resistance, which can effectively block the corrosion of steel by air, water, moisture, etc., and prolong the service life of steel.

2. Excellent weather resistance: the zinc layer can exist stably under most environmental conditions, and is not easily affected by oxidation, corrosion and other factors, and has strong durability.

3. Uniform and consistent surface treatment: The galvanized steel coil is uniformly covered with a layer of zinc through the dipping process, so that the surface of the entire steel coil is uniformly treated, and scratches, oxidation and other problems are not easy to occur.

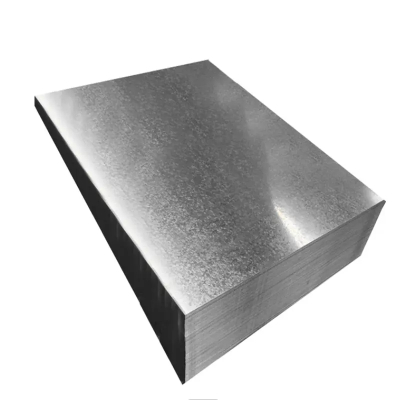

Product description

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

Product parameters

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Material | Q235 Q195 / Q235 / Q345B / DB460 ASTM/AISI/SGCC/CGCC/ |

Thickness | 0.12-6.0mm |

Width | 20-1500mm |

Zinc coating | Z40-600g/m2 |

Coil weight | 3-8 Tons or as requirement |

Surface | Galvanized Coated |

Certificate | ISO,SGS |

Product details

Meanwhile, Group company imported the most advanced technology from Germany, Japan, Belgium and America, UK etc. for iron-smelting, steel-smelting, and processing steel sheet, also equipping with the complete automatic system, then become the most advanced and biggest professional manufacturer in China at that time. Currently the group holds the rolling mill and the production lines of galvanized, galvalume and prepainted steel, and corrugation machines, with the annual production capacity of 1.2 million tons. Since the producing began, our group company insisted in arriving at the advancement in the technology field by our continuing effort. At present, the company has gained lots of trust and praise from all over the world with qualified products and good service, exporting to North and South America, Europe, South-east Asia, Middle East area and Africa.