CR Rolled MS Low Carbon Mild Steel

The corrosion resistance of stainless steel strip mainly depends on its alloy composition (chromium, nickel, titanium,silicon,aluminum, manganese, etc.) and internal structure, which plays a major role in the chromium element.Chromium has high chemical stability, can form passivation film on the steel surface, make the metal isolated from the outside world, protect the steel strip from oxidation, increase the corrosion resistance of the steel plate.The corrosion resistance decreases after the passivation film is destroyed.

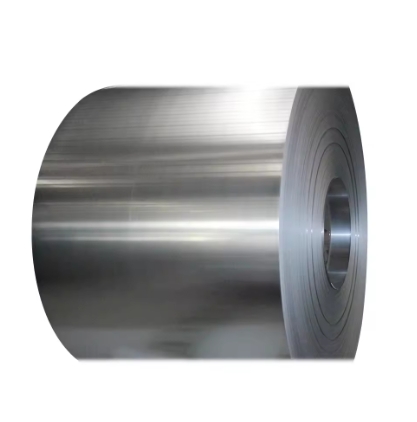

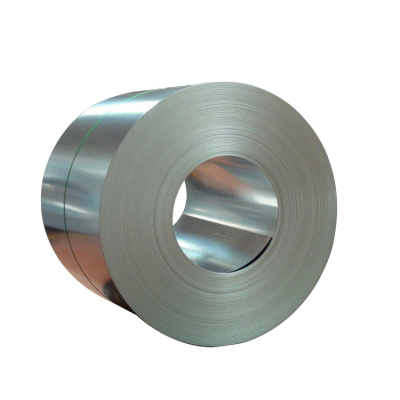

Surface overview: After the material is cold-rolled and rolled, the strip is subjected to continuous line annealing to change the

structure, grain and mechanical properties of the material to achieve the mechanical properties required by customers; Quality

rolling and tension leveling correct the shape and improve the surface fineness.

Process route: raw material NO.1/2E—rolling—degreasing cleaning—annealing—electrolysis—pickling—quenching and tempering

rolling—drawing and leveling—coil/plate finished product